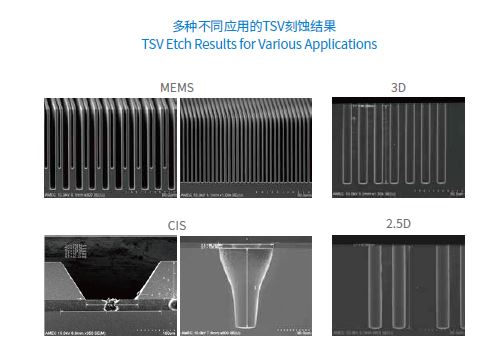

Through Silicon Via (TSV) has become a key technology for advanced packaging applications for various products such as CMOS image sensors, 2.5DICs, 3DICs and plasma dicing. The Primo TSV® tool is AMEC’s first high-density plasma TSV etch product for high-performance TSV applications. The system employs a cluster configuration design which allows for up to three dual-station process modules to be attached to the main frame. Each module can process two wafers simultaneously. AMEC offers 200mm and 300mm TSV production tools capable of etching holes with CDs ranging from hundreds of microns down to <1um, and depth of up to several hundred microns. In addition, with its strong process-tuning capabilities, the tool can generate diverse profiles based on customer requirements (i.e., vertical, cone-shaped, tapered, and more). Finally, with unique features, such as a pre-heating station, wafer-edge protection ring, and low-frequency RF pulsing bias and side gas feed, the Primo TSV is an ideal tool to deliver the technology, flexibility, and productivity needed for the TSV market.

High-productivity solution for deep silicon etching

Dual stations with inductively-coupled plasma source

High-power source RF and continuous wave or pulsed bias RF

On-board gas box with advanced fast gas switching

Wafer edge protection ring

Optical endpoint control system

Tunable dual coil

Process tunability for diverse applications

High-productivity mainframe for maximum throughput per system

Bosch and steady-state processing capabilities within the same chamber